The fragrance component (perfume component) found in flowers and leaves of plants, pericarp, roots, etc., that is extracted, is called essential oil, and is utilized in various fields including aromatherapy.

In Japan, essential oils have been used in medical and beauty treatments as well as in health fields since as far back as the Edo period (Tokugawa; 1603—1967), and in the Meiji period (1868—1912) export also began to thrive. Today, essential oils are extracted from various types of plants in Japan.

Within Wakayama Prefecture, in 2015 Nakano B.C. Co., Ltd. began manufacture and sale of the domestically produced essential oil FRAGRANT KISHU-WAKA, made with select ingredients produced in Wakayama Prefecture, and started making essential oils from citrus—namely, Satsuma mandarin, Amanatsu and Sanbokan. In 2018, essential oil from Aridagawa-produced budo sansho was added to the lineup.

The “BC” of Nakano B.C. stands for Biochemical Creation. While using agricultural produce from Wakayama Prefecture to manufacture products such as refined sake, umeshu (plum liqueur), and distilled liqueurs, the company has established connections with universities and external research institutes, and in order to contribute to people’s health through local medical-use resources, aims toward pharmaceutical intermediates emerging industries.

This time, we asked Akio Kadowaki, doctor of engineering and senior researcher at the Food Science Research Center, and Masato Suzuko, head of the manufacturing department, about the behind-the-scenes development of budo sansho essential oil, its specialties, and functional research among other topics.

Junko Kida

Interviewer/Writer

Profile

Aromatherapy consultant

President of midi Health Laboratory

http://www.kenkounokoto-midi.jp/

Representative Director of Hand-Bonding Care Association

Involved in aromatherapy since 1992, worked at herb and aromatherapy products wholesaler, and established her own business in 1997.

Has been engaged in training professionals including aromatherapists for approx. 20 years, mainly in and around Tokyo and Kamakura.

Member of the Aroma Environment Association of Japan

Member of NARD JAPAN (NARD Aromatherapy Association)

There is definitely something in this

Ms. Kida:First of all, please tell me what first made you think about extracting essential oil from budo sansho?

Dr. Kadowaki:From the beginning it has been known that anti-obesity and energy-metabolizing improvement functions are found in other spices. I started thinking that there definitely has to be something in this, since budo sansho is a spice just the same, and also called Japanese pepper in English. Research into budo sansho function is carried out in conjunction with Wakayama Medical University, and started with trying to understand its influence, first of all, when eaten.

Dr. Kadowaki, engaged in research into functions of regional plants

Budo sansho produced in Shimizu, Aridagawa Town, used in distillation

Distiller used for distilling budo sansho essential oil

Development of budo sansho essential oil begins

Kida:Why was it that you moved to distillation of essential oil, from starting out with research into understanding its influence when eaten?

Kadowaki:When mice are fed the powder from budo sansho, it is clear that there is an anti-obesity effect. From there, we started investigation into why certain components within sansho have an anti-obesity effect. But the fact is, separating out the individual components slightly lessens the effect. We wondered, “why?”

At that time, we realized something while separating the components—the aroma of the sansho wafted—and we thought perhaps that was the reason. And then we started to consider, if that was the case, then perhaps we would be able to distill the budo sansho and retain its function.

Kida:The base ingredient of the essential oil is budo sansho; it’s known as aozansho (green sansho berries) and still unripe in early summer, harvested for dried sansho when it matures in summer, and becomes akazansho (red sansho berries) when fully ripened. What type of budo sansho do you use, from which stage?

Kadowaki:The base ingredient we use is sansho gathered at the time it ripens in August, around Obon (Japanese Buddhist Festival of the Dead). Farmers dry it, and we use the pericarp part, with the inner seed removed. It’s not possible to completely remove the seeds, but there is no impact on the constituent components even if a little is left behind. The amount of essential oil in akazansho is extremely small, and leaving the berries until they fully ripen weakens the tree, so it is almost impossible to obtain the residual.

Distillation procedure

Kida:Well, before I ask you about functionality in detail, I’d like to hear more about distillation. I have heard that sansho is distilled after being frozen and then thawed at room temperature, but would you be able to tell me about the process up to distillation?

Suzuko:After grinding the sansho slightly, we add water and then to make it into a paste, it is ground further, and then put into the distillation still. Water is added to make it circulate inside the distillation still.

Kida:Why is it that you grind it in two stages, rather than adding water and grinding it all in one go?

Suzuko:That is because if we add water at once then it cannot be ground well. Also, dried sansho can heat up easily and so grinding it a little at a time is a technique to avoid thermal denaturation.

By grinding the sansho, the oil glands get crushed, and here too the aroma wafts away, so seeing if we can shorten the time taken in the process up until distillation in some way is what we pay the most attention to.

Kida:So then finally you move on to the distillation stage. Around how long does distillation take?

Suzuko:That’s an industry secret. (laughs)

Kida:I see. (laughs) Well, I would like to ask about the essential oil after distillation. Immediately after extracting oil there are some essential oils that give off a raw smell, but is that the case with sansho essential oil?

Suzuko: There is what you would call a heat smell, and that takes around 10 days to two weeks to disappear, so while keeping watch on the situation, we conduct aging. The constituent is left to stand in a room at a temperature of around 23 to 25 degrees Celsius, with light blocked out as much as possible. Immediately after distilling, the essential oil and perfume distilled water is a light-yellow color and opaque, but once it is aged it becomes mostly transparent.

Mr. Suzuko, responsible for repeated examination, striving for quality improvement in essential oil

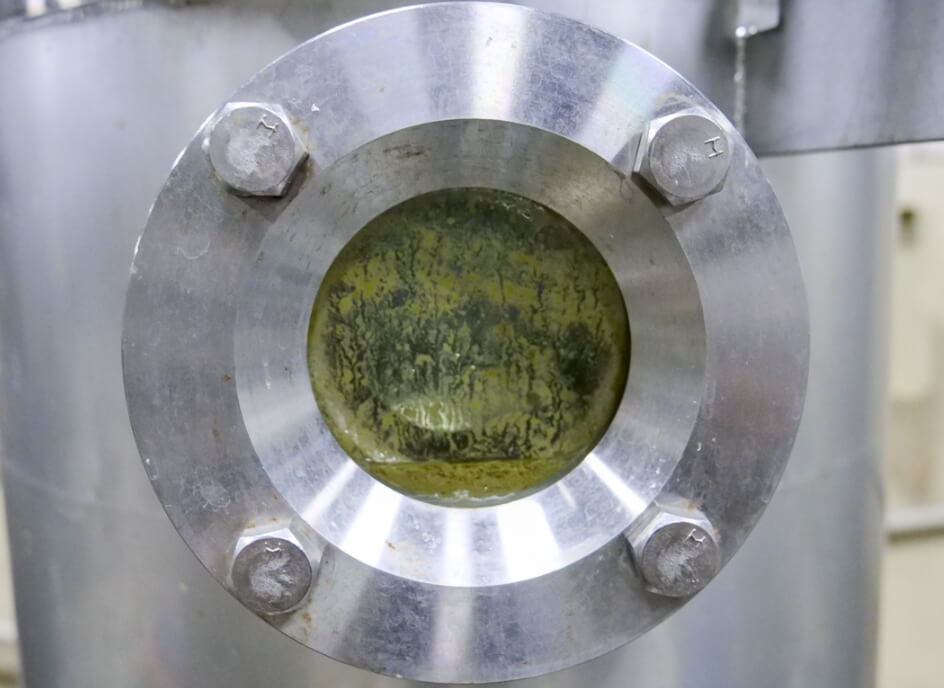

The state inside the still can also be monitored during the distillation process

Extensive uses of budo sansho

Extensive uses of budo sansho

Extensive uses of budo sansho

Extensive uses of budo sansho